IBOP

- Complete diverter controls with sequencing options and indicators.

- Alarm systems to alert operator of potential issues and if drilling operations should stop to prevent a possible uncontrolled well situation.

- Components have been field tested for decades to ensure dependability, maximum life and minimal downtime service.

- It work with most PLC manufacturers’ control equipment to be compatible with your rig electronics.

- It can be designed and manufactured to any specification including ATEX, all European Directives, GOST, NORSOK, DNV, ABS and all major oil companies specifications.

- Technical Specification

- More Details

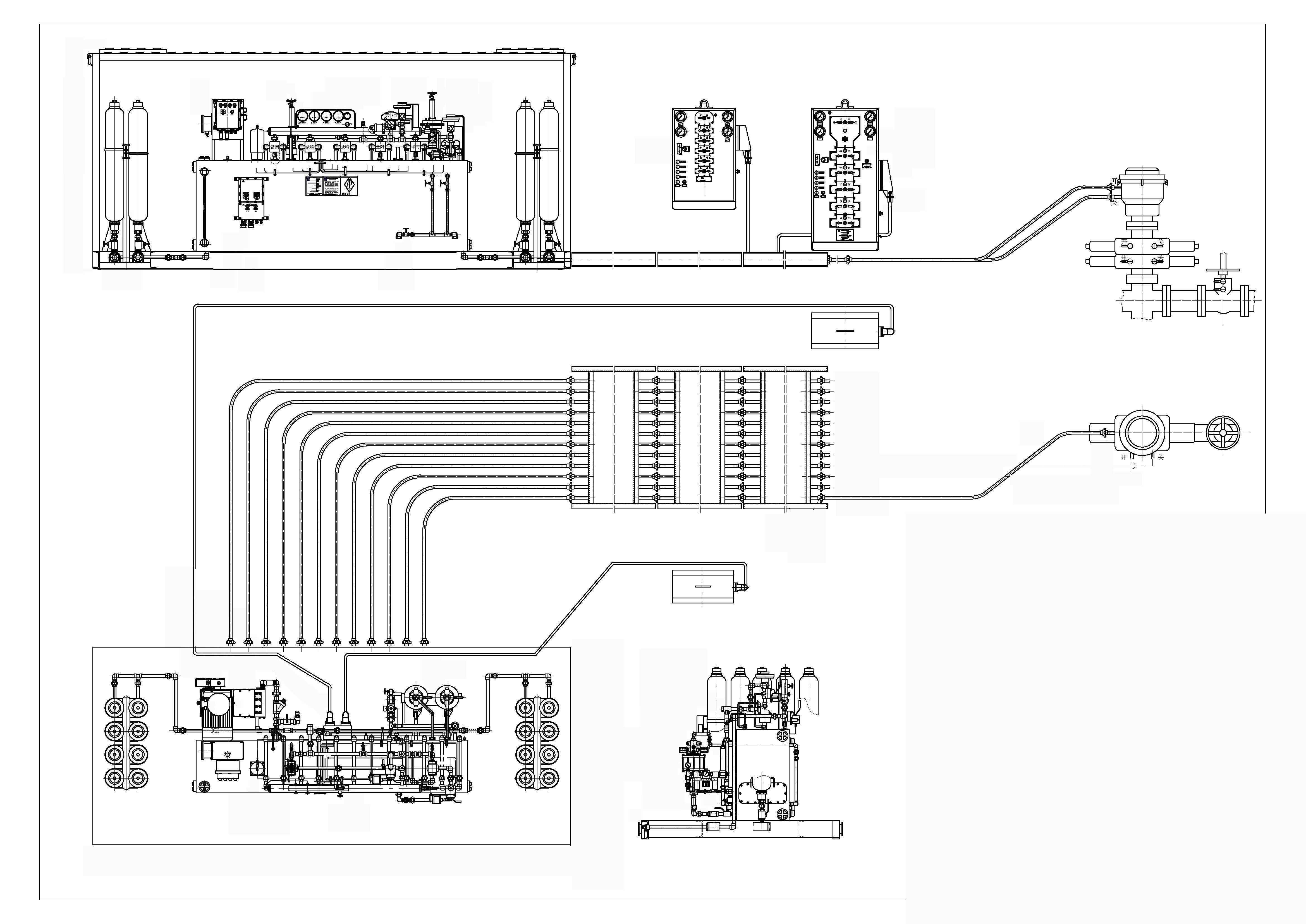

- Drawing

- Contact Us

| Model | Number of controlled objects | Accumulator unit | Explosion-proof motor Power

(Kw) |

Pump system displacement | Rated operating pressure of the system (Mpa) | Maximum operating pressure of the system (Mpa) | |||

| Total volume (L) | Available liquid volume (L) | Installation mode | Triplex pump (mL/r) | Pneumatic pump (mL/stroke) |

|||||

| FKDQ1920-13 | 13 | 80×24 | 960 | Side / Rear | 18.5×3 | 80×3 | 120×5 | 21 | 31.5 |

| FKDQ1600-14 | 14 | 80×20 | 800 | Side / Rear | 18.5×2 | 80×2 | 120×4 | 21 | 31.5 |

| FKDQ1600-12 | 12 | 80×20 | 800 | Side / Rear | 18.5×2 | 80×2 | 120×4 | 21 | 31.5 |

| FKDQ1600-10 | 10 | 80×20 | 800 | Side / Rear | 18.5×2 | 80×2 | 120×4 | 21 | 31.5 |

| FKDQ1440-14 | 14 | 60×24 | 720 | Side / Rear | 18.5×2 | 80×2 | 120×4 | 21 | 31.5 |

| FKDQ1280-10 | 10 | 80×16 | 640 | Side / Rear | 18.5×2 | 80×2 | 120×3 | 21 | 31.5 |

| FKDQ1280-9 | 9 | 80×16 | 640 | Side / Rear | 18.5×2 | 80×2 | 120×3 | 21 | 31.5 |

| FKDQ1280-8 | 8 | 80×16 | 640 | Side / Rear | 18.5×2 | 80×2 | 120×2 | 21 | 31.5 |

| FKDQ1280-7 | 7 | 80×16 | 640 | Side / Rear | 18.5×2 | 80×2 | 120×2 | 21 | 31.5 |

| FKDQ1200-17 | 17 | 60×20 | 600 | Side / Rear | 18.5×2 | 80×2 | 120×3 | 21 | 31.5 |

| FKDQ1200-9 | 9 | 60×20 | 600 | Side / Rear | 18.5×2 | 80×2 | 120×3 | 21 | 31.5 |

| FKDQ1200-8 | 8 | 60×20 | 600 | Side / Rear | 18.5×2 | 80×2 | 120×2 | 21 | 31.5 |

| FKDQ960-8 | 8 | 60×16 | 480 | Side / Rear | 18.5×2 | 80×2 | 120×2 | 21 | 31.5 |

| FKDQ960-7 | 7 | 60×16 | 480 | Side / Rear | 18.5×2 | 80×2 | 120×2 | 21 | 31.5 |

| FKDQ800-8 | 8 | 40×20 | 400 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 800-7 | 7 | 40×20 | 400 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 800-6 | 6 | 40×20 | 400 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ720-7 | 7 | 60×12 | 360 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 720-6 | 6 | 60×12 | 360 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 640-6 | 6 | 40×16 | 320 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 640-5 | 5 | 40×16 | 320 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 480-5 | 5 | 40×12 | 240 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ 480-4 | 4 | 40×12 | 240 | Side / Rear | 18.5 | 80 | 120 | 21 | 31.5 |

| FKDQ320-5 | 5 | 40×8 | 160 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ320-4 | 4 | 40×8 | 160 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ320-3 | 3 | 40×8 | 160 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ240-3 | 3 | 40×6 | 120 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ200-4 | 4 | 25×8 | 100 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ160-3 | 3 | 40×4 | 80 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ150-2 | 2 | 50×3 | 75 | Side / Rear | 15 | 60 | 120 | 21 | 31.5 |

| FKDQ125-3 | 3 | 25×5 | 62.5 | Side / Rear | 7.5/11 | 28 | × | 21 | 21 |

| FKDQ80-3 | 3 | 40×2 | 40 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ80-2 | 2 | 40×2 | 40 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ75-2 | 2 | 25×3 | 62.5 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ63-2 | 2 | 63×1 | 31.5 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ50-2 | 2 | 25×2 | 25 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ40-2 | 2 | 40×1 | 20 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ25-2 | 2 | 25×2 | 12.5 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

| FKDQ25-1 | 1 | 25×2 | 12.5 | Side / Rear | 7.5 | 28 | × | 21 | 21 |

Accumulator unit for BOP stacks is a very important equipment which controls BOP stacks and gate valves controlled by hydraulic pressure especially in drilling and workover operations. It is necessary to accurately operate and maintain the hydraulic control system. It consists of remote control system, driller’s panel, air cable (except electrical type), pipe rack (electrical warming system available for cold area), high pressure manifold, protection room, etc.

It can be divided into two types: Electrical type FKDQ series and Pneumatic type FKQ series.

Learn More When Inquiring

Buyer’s Guide

Please send us your inquiry with detail item description or with Model number. If there is no packing demand we take it as our regular exported standard packing. We will offer you an order form for filling. We will recommend you the most suitable model according to information you offered.

We can give you really high quality products with competitive price. We have a better understanding in Chinese market, with us your money will be safe.

Get Quick Response

Lake Petro is located in Dongying City, which is famous for Shengli Oilfield and the largest manufacturing hub of petroleum equipment in China. Following the principle of “quality first, science and technology innovated, people oriented”, every Lake Petro person is sparing no effort to provide the customers with best products and services. Our products are based on advanced production line and testing equipment, our products are designed and manufactured according to certification of ISO, GOST, etc.